Studies & Concepts

From waste generation to GHG balance – your partner!

Do you need studies on waste generation, waste treatment and waste prevention as well as on biomass and residual material potential? Then we at GNS can provide you with expert help! We are your experienced partner for the conception, implementation and evaluation of results of practice-oriented and scientific studies in the field of waste management and biomass use. In addition, we offer advice and studies on the analysis and optimization of material cycles and material flows.

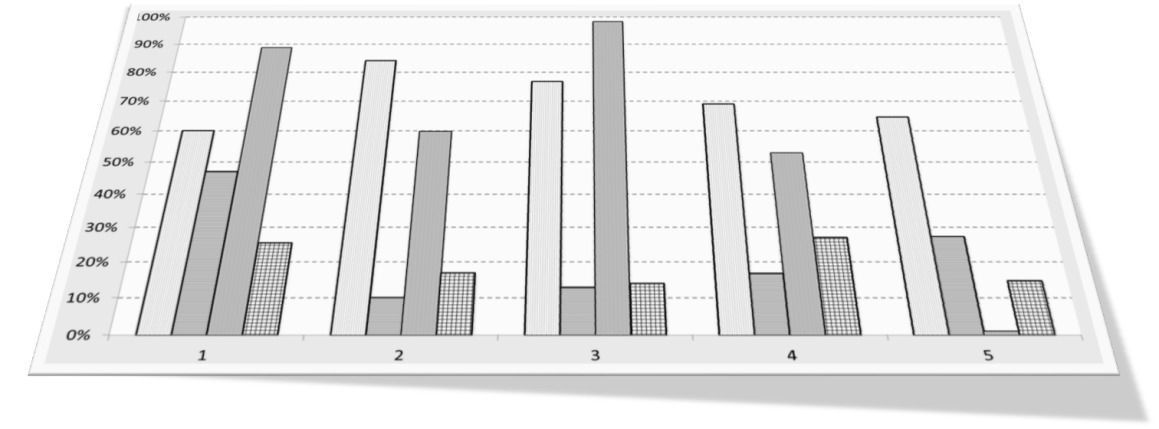

Methodology of our practice-oriented and scientific studies at a glance:

primary research and surveys

research of secondary sources

evaluations of even large amounts of data

visualization of the results

Practical recommendations for action

We prepare company-related and product-related environmental assessments (LCA, GHG, CCF, PCF).

We support your ecological, economic, social and sustainable product development.

We support you by presenting your path and success at conferences and workshops.

Do you need a carbon footprint, a life cycle assessment, a greenhouse gas balance or a sustainability assessment? Our company in Halle, which specializes in testing, consulting and support for sustainable products, processes and procedures, is also your partner for this.

And this is how you as a company benefit from a sustainability assessment¹:

integration into the corporate strategy

facilitating product placement

Opening the doors to potential investors and banks

The requirements of environmental protection and sustainability go hand in hand. We as the GNS team always keep these requirements in mind for our customers. Our team has over three decades of academic experience in the field of environmental and process engineering. Many investors, planners and plant operators have already benefited from the knowledge of our process chemists and process engineers. We look forward to hearing from you.

¹: GNS is certified by GUTcert

Our references

Evaluation of an ecologically, economically and socially sustainable use model for weed control with biofiber mulch mats in viticulture compared to conventional alternatives (2022)

Partial study within the framework of the model project “Sustainable viticulture with weed protection through biodegradable mulch mats in the Saale-Unstrut wine-growing region”, funded by the BMWi in the federal funding measure “Unternehmen Revier”

Savings of GHG emissions in the production of paper from biofibers after biogas production compared to paper production from cellulose (2021)

study commissioned by a private person

State Office for Environment, Agriculture and Geology in Saxony (2020)

Study to ensure the proper disposal of old medicines in the Free State of Saxony.

State Office for Environmental Protection and Agriculture Saxony-Anhalt (2017)

Study to develop the basis for a waste prevention contribution by the state of Saxony-Anhalt - prevention of food waste.

Project developer for renewable energy technologies from England (2015)

Preparation of a technology overview "General Assessment of Advanced Conversion Technologies by Gasification / Pyrolysis".

Project developer for renewable energy technologies from Munich (2011)

Determination and evaluation of potentials of straw-containing biomass for a plant site in Germany.

Reducing emissions in livestock farming through holistic measures in manure treatment (2006)

Study commissioned by the Ministry of Agriculture and Environment of Saxony-Anhalt

Ecological and economic evaluation of the use of EPDM devulcanizate compound (2004)

Partial study within the framework of the project: “Implementation of the circular economy in the rubber processing industry” of the interest group Kunststoffrecycling Sachsen eV (IG KURIS)

Ecological and economic evaluation and comparison of hemp fiber reinforced with glass fiber reinforced injection molded products (2002)

Partial study in the joint project “Substitution of glass fibers in injection molded parts by plant fibers – development of a technological line”, funded by the DBU