F&E-Project

Cooperation project 3D printing components from sustainable biogenic materials

Development of flexible insulation and absorption panels made of sustainable natural fibers using additive manufacturing and parametric design

Period: 12/2023 - 04/2026

Sponsors: funded by BMWK, central innovation program for medium-sized businesses ZIM

Project partners: Additivum, Lithium Designers and the Institute for Printing Machines and Printing Processes (IDD) at TU Darmstadt

Objectives: The aim of the project is to develop a sustainable material that can be used to produce irregularly shaped absorption or insulation panels cost-effectively and digitally. This is made possible by the use of parametric design and 3D printing.

GNS: Pioneering work in 3D paste printing

GNS develops innovative reaction mixtures for 3D paste printing. Biogenic raw and residual materials from agriculture, such as Magaverde® biofibers from biogas plants, as well as minerals and other natural additives are processed into a multi-component system.

Additive: Revolution in 3D printer construction

The start-up Additivum from Darmstadt is focusing on the development of a 3D printer with a special conveyor unit and mixing device. This ensures the homogenization of the components used and prepares the resulting paste for additive manufacturing.

Lithium Designers: Expertise in freeform glass facades

Lithium Designers GmbH offers an economical solution for free-form glass facades. Using the developed Li3 method and the in-house software Li3M, the company plans and certifies new and additively manufactured building products.

IDD of TU Darmstadt: Research and Development in Large-Scale 3D Printing

The Institute for Printing Machines and Printing Processes (IDD) at TU Darmstadt uses its comprehensive knowledge and methods to characterize the materials and optimize the new printing process.

Joint project: Chemical production at biogas plants (CapUp)

Chemical production at biogas plants – Upscaling of a process for the production of medium-chain carboxylic acids from regional residues (2021 to 2023)

Period: 02/2023 - 07/2023

Sponsor: funded by the BMWK in the “Industrial Bioeconomy” program

Project partners: German Biomass Research Center (DBFZ), Helmholtz Centre for Environmental Research (UFZ)

Associated partners: Balance Erneuerbare Energien GmbH, VNG AG, Fuchs Lubricants Co., Kelterei Sachsenobst GmbH

Objectives: The process for producing carboxylic acid from biomass developed on a laboratory scale by DBFZ and UFZ is now to be taken to the next technological level. The sub-objectives shown below are being pursued in order to achieve a level of technological maturity suitable for market launch.

Scaling of the entire process chain of a biorefinery process for the production of chemicals, biogas and fertilizer by a factor of 10 and demonstration in the TRL by 5 to 6.

By scaling up the process to application-oriented equipment, process data is to be obtained as a basis for a reliable process evaluation and sample quantities are to be produced for extensive product tests. The DBFZ's multi-purpose demonstration plant is used for this purpose.

In addition to coordinating the project, GNS carries out the procedural, economic and ecological assessment and derives a utilization concept with the involvement of the associated partners.

Joint project: Sustainably printable and micro-structurable biofiber paper

Sustainably printable, surface-treated and micro-structureable biofiber paper for packaging and 3D products (2021 to 2023)

Period: 7/2021 - 06/2023

Sponsor: funded by the BMBF in the pilot program “WIR! – Change through Innovation in the Region” of the program family “Innovation & Structural Change”

Project partners: BENAS Biopower Group, Institute for Printing Machines and Printing Processes (IDD) at TU Darmstadt, Druckerei Werbeteam GbR

Associated partners: Kartonagenwerk Leipzig Land GmbH, Hallesche Behindertenwerkstätten eV, Möbel- und Leistenfertigung Wippra GmbH, Freudenberg Industrie Siebdruck GmbH and others

Objectives: Not only should our Magaverde biofiber paper be sustainably produced and completely biodegradable, the printing inks and surface treatments used should also be. To this end, we have developed a joint project with partners from science and industry as part of the GRAVOmer network (www.gravomer.de). In this project, we are developing innovative ways and methods for sustainable printing and surface treatment that are suitable for industrial processing.

All finishing processes, such as printing and surface treatment of the paper, must be ecologically harmless in order to avoid harmful effects on the environment when the products made from them are returned to the natural cycle after use.

New processing methods are intended to create high-quality optical, haptic and other property-enhancing effects that significantly improve the variety of possible products and their value without compromising the original character of the sustainable biofiber paper.

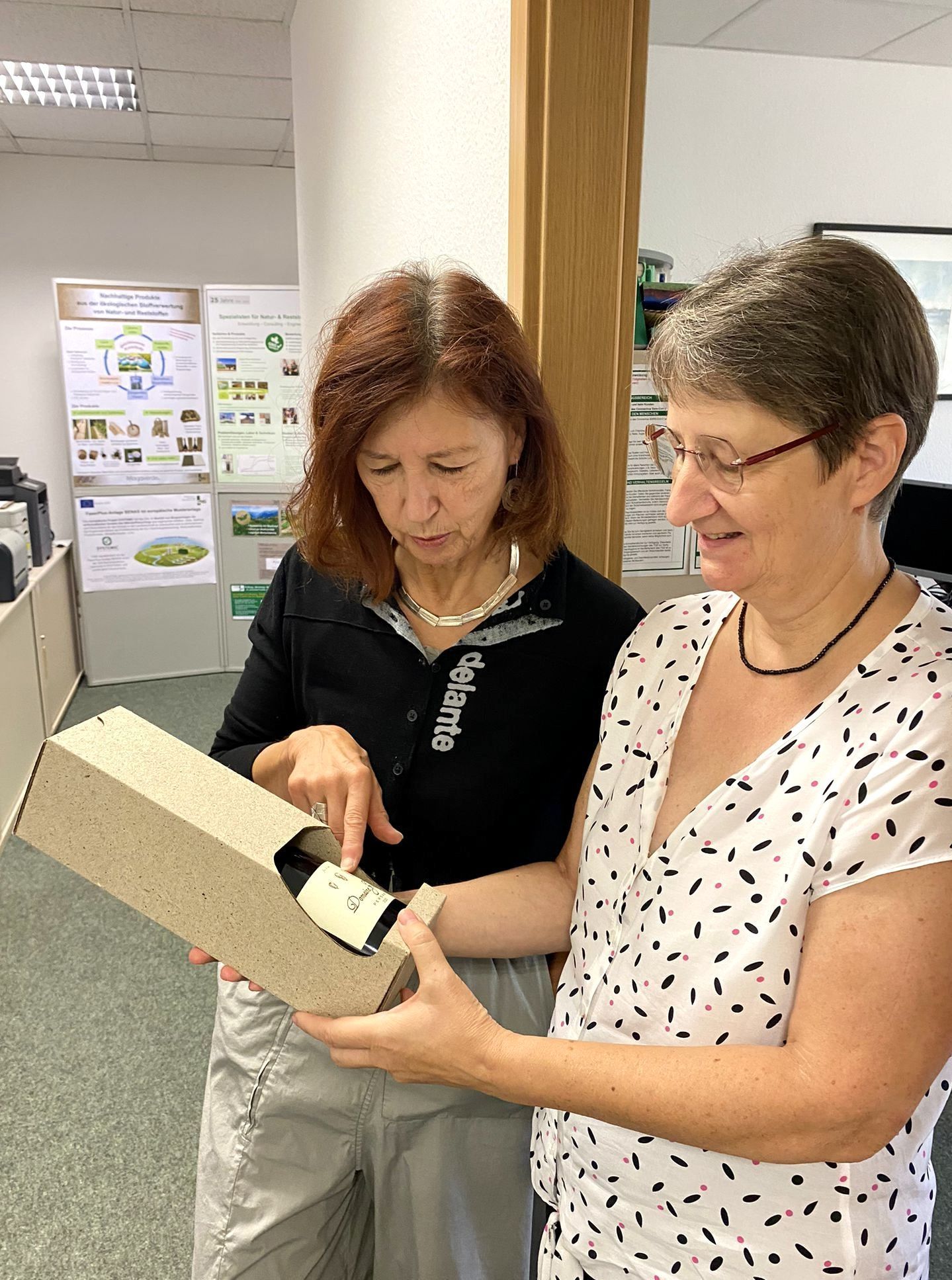

Demonstrators, i.e. products such as packaging and cardboard boxes, are to be created together with the associated partners in order to test the results of the development for practical suitability.

Project video: www.youtube.de

Model project for sustainable viticulture with Magaverde mulch mats

Model project "Sustainable viticulture with weed protection through biodegradable mulch mats in the Saale-Unstrut wine-growing region" (2021 - 2022)

Period: 1/2021 - 12/2022

Sponsor: funded by the BMWi in the federal funding measure “Unternehmen Revier”

Project partners: Winegrowers' Association Freyburg-Unstrut eG, Landesweingut Kloster Pforta and other wineries in the region, Research Institute for Post-Mining Landscapes eV (FIB eV)

Objectives: The Saale-Unstrut wine-growing region, with its more than 1,000-year history, is an important pillar in the Burgenlandkreis cultural region. The entire area along the Saale and Unstrut is a Zone II protected area for groundwater and spring water extraction. Growing wine on the steep slopes of Saale-Unstrut without chemical herbicides and pesticides therefore protects the environment and our health. However, this is associated with increased manual work in the soil cultivation.

Together with the Freyburg-Unstrut winegrowers' association and several wineries in the Saale-Unstrut region, the use of biodegradable Magaverde mulch mats or mulch papers as protection against weeds will be demonstrated and suitable installation techniques will be tested.

The Research Institute for Post-Mining Landscapes in Finsterwalde is providing scientific support by measuring weed suppression, soil moisture, water infiltration and plant vitality.

As a result, economic models are being developed so that sustainable weed control in viticulture can be widely used in the region and beyond.

Growth core abonoCARE®

Closed technology chains for nutrient recycling from organic residues – organic residues to advanced nutrient (2019 - 2022)

Period: 4/2019 - 12/2022

Sponsor: funded by BMBF in the funding program “Innovative regional growth centers”

Project partners: Consortium of 11 industrial partners and 6 research partners in the Central Germany region, www.abonocare.de

Objectives: Innovative small and medium-sized companies from the field of recycling organic waste have joined forces under AbonoCARE in order to use their combined innovative power to develop and economically exploit closed technology and value chains from the waste material to the product.

The core of AbonoCARE is made up of partners with different technologies for conditioning, conversion, fractionation and packaging. These are expanded by companies and institutes that offer extensive analytical capacities and laboratory and test facilities for product and process development. In total, the following 4 areas are represented:

Conditioning technologies for the preparation of organic residues

Process for sewage sludge utilization with production of phosphorus fertilizers and biochar

Process for digestate treatment with nitrogen recovery

Process for the production of fertilizer granules and special soil mixtures

In Area 3, the following developments are carried out and services offered under the leadership of GNS:

Processes and plants for the treatment of liquid organic residues with the production of high-quality fertilizer products

Production of high-quality fertilizer products: ASL (25 – 40%), adapted special N fertilizer solutions (N, N+S, NPK, NPK+S), AHC product, MAP fertilizer

research and development expertise in the field of nutrient recovery

EU project SYSTEMIC

Circular Solutions for Biowaste - Demonstration and evaluation of innovative technologies for closing the loop and recovering plant nutrients from biogenic waste (2017 - 2021)Period: 6/2017 - 11/2021Funding: funded by the European Union's HORIZON 2020 research and innovation programProject partners: Consortium of 15 partners and 7 EU countries www.systemicproject.eu

Goals:

Using 5 demonstration plants in Europe, SYSTEMIC is demonstrating for the first time how innovative recycling technologies can be used to extract high-quality plant nutrients from organic waste, liquid manure and solid manure and how ecologically and economically sustainable business models can be created. With the FaserPlus plant at BENAS, GNS represents one of the 5 demonstration sites and the German site.

SYSTEMIC also offers 10 European biogas plants the free evaluation of integrated recycling technologies with the aim of making the operation of the biogas plant more profitable, stable, sustainable and independent of subsidies.

The results of these studies will be prepared in case studies and concepts and for policy advice in order to disseminate intelligent solutions for the targeted recycling of plant nutrients from biogenic residues and waste materials throughout the EU so that agricultural and urban cycles can be closed sustainably.

Joint research project Biogas-Fiber-Plus

Production and use of high-quality materials from by-products of biogas plants (2015 - 2017)Period: 3/2015 - 9/2017Sponsor: funded by the Federal Ministry of Education and Research (BMBF) in the BioEconomy excellence clusterProject partners: GNS (network management), DBFZ German Biomass Research Center gGmbH - Leipzig (D), BENAS GmbH - Vorwerk (D), Kronospan GmbH - Lampertswalde (D), La Mont GmbH - Berlin (D), ORmatiC GmbH - Berlin (D), eutec Ingenieure GmbH - Dresden (D), associated partner: KTG Energie AG - Hamburg (D)

Technical and scientific objectives:

Utilization of fiber-rich fractions from fermentation residues as wood substitute

Development and testing of special equipment for the FiberPlus process

large-scale piloting of the FiberPlus process and use of biogas fibers in wood-based material production

Project results:

Testing of a pilot plant for 2 m³/h throughput

Conversion of the large-scale BENAS plant to a FiberPlus plant with continuous operation since 10/2016

Testing and optimizing fiber usage at Kronospan

Derivation of the ecological-economic evaluation of the overall system

Joint research project HolzgasPlus

Joint research project to reduce benzene in wood-gas-powered CHP plants, with testing of new afterburning catalysts from GNS.Period: 11/2012 - 6/2014Sponsor: Federal Ministry for the Environment, Nature Conservation and Nuclear Safety, Project Management JüllichProject partners:Fraunhofer Institute for Solar Energy Systems ISE (coordinator)Company partners include Burkhardt GmbH, Ligento green power GmbH, Schnell Motoren AG, Spanner RE2 GmbH, Stadtwerke Rosenheim GmbH Co. KG (SWRO), SWU Energie GmbH, GNS mbH2013: Successful tests with GNS afterburning catalystsWith new bulk catalysts from GNS, high conversion rates for CO and benzene were achieved in tests with engine exhaust gas from wood gas production in plants run by partners ISE and SWRO.

GNS afterburning catalysts: By using a catalyst combination consisting of a particularly powerful oxidation catalyst and a robust protective catalyst, the catalyst poisons can be intercepted in the inexpensive protective catalyst before they enter the highly active oxidation catalyst. This means:

Safe compliance with emission limits for CO, benzene and other pollutants throughout the entire operating period

Lower costs and improved service life of catalysts

Joint research project on fermentation product fibers

Joint research project on the material use of NH4-N-free digestate fibres from biogas plants in chipboard and MDF production.

Period: 4/2012 - 3/2014 Sponsor: German Federal Environmental Foundation (DBU) Project partners: Nova-Institut GmbH - Hürth (D), Glunz AG - Meppen (D), BENAS GmbH - Vorwerk (D), SSM-Technology - Nauen (D)

Joint research project ANAklär

Modification and adaptation of the ANAStrip® process for nitrogen recovery for sewage treatment plants with sewage sludge digestion with construction and operation of a pilot plant under the scientific management of GNS.

1st phase: Laboratory tests (2011)2nd phase: Construction and operation of a container pilot plant for sewage sludge digestion, nitrogen removal and sludge treatment (2012-2013)Period: 2011 to 2014Sponsor: Austrian Research Promotion Agency FFG, program line COINProject partners: AIM Technical Solutions GmbH - Timelkam (A), University of Natural Resources and Life Sciences Vienna, IFA Tulln (A), HIPI Ziviltechniker GmbH - Vöcklabruck (A), SSM-Technology - Nauen (D)